Fully automatic machines have revolutionized the manufacturing industry, especially in the realm of perfume filling. These hands-free, machine-driven systems are designed to handle a wide range of tasks with minimal huma Aerosol filling equipment n intervention, making them highly efficient and cost-effective for businesses.

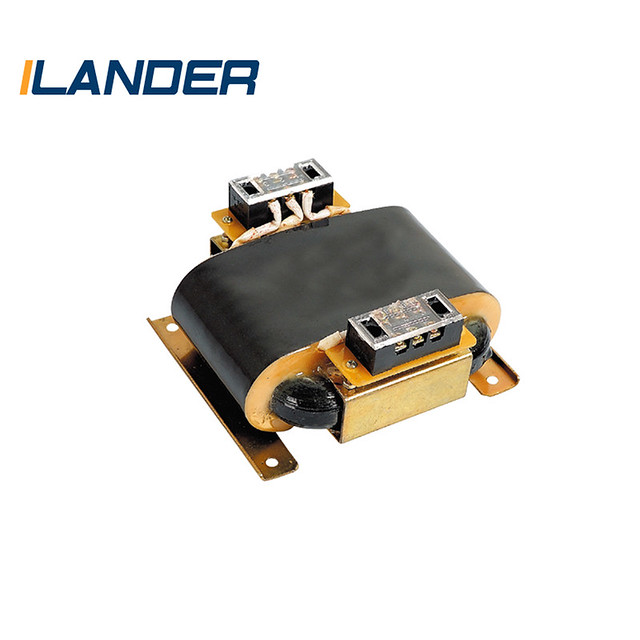

One such example is the Fully automaticperfume filling series. This innovative Aerosol filling equipment utilizes state-of-the-art technology to accurately dispense perfumes and other liquid distillate filling machine products into containers. The distillate filling machine is another key component of this system, ensuring precise measurements and consistent results every time.

The manufacturing process using fully automatic robotic machines begins with loading empty con Fully automatic tainers onto the conveyor belt. The system then fills each container with the desired amount of perfume before moving on to capping and sealing processes. All these steps are

seamlessly integrated into one continuous operation, saving time and resources for manufacturers.

The main advantage of using fully automatic perfume filling machines lies in their high efficiency and accuracy. These machines can fill hundreds of bottles p Machine-driven er minute with minimal waste or errors, leading to significant cost savings fo perfume filling series r businesses. Additionally, their hands-free operation reduces the risk of contamination and ensures product quality remains consistently high.

To use a fully automatic perfume filling machine, operators simply need to set up the parameters for each batch through an intuitive control panel. Once everything is configured correctly, the machine can run autonomously while operators focus on other tasks within Fully automatic the production line.

When selecting a perfume filling machine for your business, it’s essential to consider factors such

as production capacity, bottle sizes supported, and compatibility with different types of liquids. Fully automatic machines like the ones men Hands-free tioned above are ideal for larger-scale operations where speed and precision are crucial requirements.

In conclusion,

companies that invest in fully automatic robotic machines for their perfume filling processes stand to benefit from increased efficiency,

reduced costs,

and improved product quality.

These advanced systems offer a streamlined solution that simplifies manufacturing o Robotic perations

while delivering consistent results that meet customer expectations.

Overall,fully-automatic robotic machines have become indispensable

tools in today’s competitive market,making them a worthwhile investment for any business lookingto optimize its production processes