Benefits of a Custom Brushless Motor

Motors are the heart of equipment and having a high quality, robust and reliable one will make or break your design. This is especially true for airborne applications.

Using brushless motors avoids the need for a commutator and brushes which reduces noise, vibration and heat in your equipment. Various strategies are employed to control commutation, including using rotary encoders to directly measure the rotor position.

Commutation

Brushless motors eliminate the need for brushes and mechanical commutator by using electronic control to switch currents to the rotor coils. The rotor coils are attracted and repelled by stationary magnets in the stator, rotating them to produce torque. Electronic commutation does not cause the sparking and wear that is a common problem with brushed DC motors, increasing reliability and reducing maintenance.

Hall sensors mounted on the rotor detect the position of the permanent magnets and transmit this information to the motor controller. This enables the control circuit to determine the angular position of the motor and control the currents passed to the rotor. The custom brushless motor most popular commutation technique is trapezoidal, which involves switching on and off the rotor windings in pairs, each time changing the direction of current flowing through one of them. Other commutation methods, such as sinusoidal commutation, use more complicated control electronics but reduce the torque ripple that is seen with trapezoidal commutation.

An “H-bridge” made of semiconductor switches – usually transistors, IGBTs or MOSFETs – is used to switch the current through the rotor coils in order to control their speed and direction of rotation. An encoder can be used to monitor the commutation position of the motor and the encoder signal can be synchronized with the pulse width modulated signal from the controller in order to determine when each phase of the H-bridge is activated. This allows the precise timing of the currents to be controlled for smooth motion with minimal power losses.

Electronics

Unlike traditional brushes, brushless motors have no components that wear and require periodic replacement. They use an electronic method of commutation that is less complicated than the brush-and-commutator approach in brushed DC motors. Instead of using sliding contacts, a controller sends a three-phase signal to the coils in the stator that control current flow, flipping the direction of current every revolution of the rotor to maintain rotation.

The amount of brushless motor torque generated depends on the size of the magnet, its copper content in the winding, and its magnetic flux path. Portescap engineers focus on maximizing these elements during the design phase so the motor can deliver the right speed and load for its intended application.

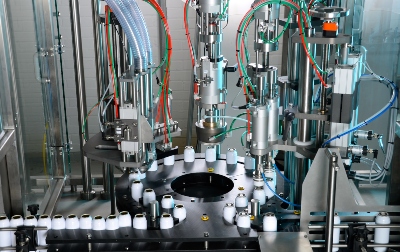

BLDC motors are favored for their superior performance in a variety of applications. They have a good power-to-weight ratio, making them ideal for cordless tools and RC vehicles. Their higher efficiency and longer lifespan also makes them a preferred choice for applications like heating and cooling systems, and industrial engineering processes such as welding, painting, and product assembly.

FAULHABER specializes in developing custom electronically commutated BLDC motors that meet specific application requirements, including power density, energy savings, and durability. Our low-voltage motors are available with a SolidSlot architecture, which eliminates costly and unreliable contractor parts, as well as with incremental or absolute encoders to enable precise positioning.

Design

When designing equipment that converts electrical signals into mechanical energy for movement, a motor is an essential component. Among the various motor types, brushless DC (BLDC) motors are especially popular because of their efficiency and controllability.

Brushed motors use a mechanical commutation that requires brushes to make contact with the rotating rotor and commutator, causing them to generate torque ripple, a pulsation of power that creates vibration and mechanical noise. This can cause the rotor to accelerate or decelerate unevenly and can limit the rated rotational speed of the motor.

In contrast, BLDC motors have no brushes and can achieve tens of thousands of hours of life with limited wear on the ball bearings. The motor also produces less electrical noise and interference, making it better suited for medical or other quiet applications.

BLDC motors use Hall Effect sensors in the rotor to determine when and which coils to energize, eliminating the need for mechanical contacts between a commutator and brushes and minimizing power losses in the commutation process. They are also designed to have a large clear aperture inside diameter that makes it easy to pass light, wiring or plumbing through the center of the motor.

Depending on the application, a custom BLDC motor can be configured with a variety of shaft modifications including hollow shafts, special materials, coating and plating. Lead length, type and connector options, encoders and other accessories can also be customized to meet specific application requirements.

Applications

Custom BLDC motors offer a variety of benefits over traditional brushed DC motors. They are ideal for battery-powered devices where increased efficiency translates into longer battery life. The elimination of brushes also means less noise, longer lifespan by eliminating commutator wear, and reduced electromagnetic interference (EMI).

Brushless motors are commonly found in applications like automotive seat adjustment motors that require precision motion and long service life. These motors High power brushless motor are also used in industrial applications like CNC machine tools, robotic systems and other industrial equipment. They can also be used in aerospace equipment where they provide resistance to shock and harsh environments.

Due to their compact size and low power consumption, BLDC motors are used in a wide range of consumer and commercial applications. They can also be used for servo motors in applications where high speed and accurate positioning are the goals.

Brushed DC motors require environmental humidity to lubricate the brushes and commutator, causing wear and shortening the motor’s lifetime. The lack of this lubrication makes brushless motors better suited to applications that are in dry or vacuum settings. These include special laboratories, aircraft designs and other commercial and military devices. They also operate quietly and without the need for a commutator, making them more suitable to medical and food applications where acoustic noise is an issue.