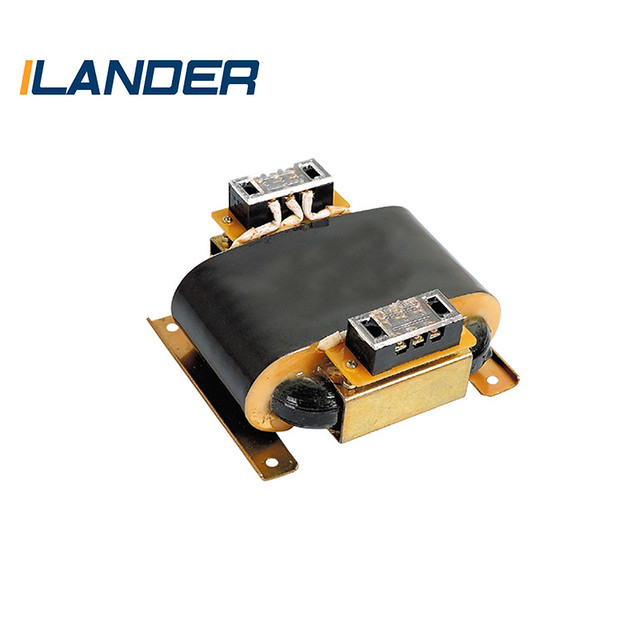

AC Motor: Manufacturing, Characteristics, Advantages and Usage

AC motor is an essential component in various industries as it Single-phase AC induction motor provides electrical energy to mechanical motion. In this article, we will explore the manufacturing process of AC motors, their characteristics and advantages, how to select the right product, and conclude with its overall significance.

Manufacturing Process:

The production of AC motors involves several crucial steps. Firstly, the stator core is manufactured b Induction motor y laminating silicon steel sheets for efficient magnetic flux distribution. Then, copper windings are carefully placed into the slots on the stator core. The rotor consists of cylindrical laminations with aluminum or copper conductors inserted on their surface. Finally, all components are assembled into a sturdy housing with bearings for AC motor smooth operation.

Characteristics:

AC motors exhibit various characteristics that make them suitable for numerous applications. One significant feature is the ability to change speed according to load requirements by utilizing variable frequency drives (VFDs). Moreover, these motors have excellent reliability due to their simple construction without slip rings or brushes present in DC motors. They als AC motor o offer high power efficiency during operation.

Advantages:

When compared to other types of electric motors such as DC or single-phase induction motors,

AC Motors excel in several areas. Firstly,

their maintenance cost is relatively lower since they have fewer wearing parts.

Additionally,

these motors do not require periodic brush replacement like DC AC motor wholesale counterparts.

Furthermore,

they can efficiently operate at varying speeds hence providing flexibility in different industrial applications

save space as multiple tasks can be performed using a single unit.

Usage Method:

To use an AC motor effectively,

1) Determine your application’s torque requirements – understanding torque needs helps select an appropriate motor size.

2) Choose between synchronous or induction type – depending on whether precision speed control is needed.

3) Establish power supply compatibility – ensuring voltage/frequency requirements align with availa AC motor ble infrastructure.

4) Select optimal cooling method based on environmental factors – air-cooled or liquid-cooled designs.

5) Install proper safety measures – utilizing circuit breakers, protective enclosures, and grounding protocols.

How to Select AC Electric motor Motors:

When selecting an AC motor, consider the following factors:

1) Determine power requirements – match the motor’s horsepower rating with your specific application needs.

2) Evaluate operating conditions – assess temperature range, humidity levels, and ambient surroundings for optimal performance.

3) Review load characteristics – analyze duty cycles to select a suitable motor that can handle intermittent or continuous operation.

4) Consider noise and vibration levels – opt for motors designed with low noise emission properties if necessary.

Conclusion:

AC motors are indispensable in nume AC motor rous industries due to their manufacturing flexibility, desirable characteristics like efficient speed control and high reliability. Their advantages over other motor types make them a popular choice among manufacturers worldwide. By carefully considering usage methods and selection criteria,

one can ensure the right AC motor is chosen based on specific industrial requirements.

In co AC motor company nclusion,

the diverse applications of AC motors make them crucial components across various sectors including automotive, HVAC systems,

and manufacturing processes. Understanding their manufacturi

ng process

characteristics,

advantages,

usage methods,

and selection criteria is vital for anyone seeking reliable electrical energy-to-mechanical motion conversion. Through continued research

development

innovation within this field we can expect even more advanced yet efficient electric motors in the future.