Aerosol Filling Equipment: Enhancing Efficiency and Precision

Introduction:

In the rapidly evolving industrial world, where demand for consumer products is soaring high, efficient and precise manufacturing processes have become crucial for businesses to stay competitive. One such essential process in various industries is aerosol filling. Aerosol fi Filler for propellant sprays lling equipment plays a pivotal role in ensuring the accurate and efficient production of various aerosol produc vape filling machine for sale ts. This article explores the different aspects of aerosol filling equipment, including its manufacturing process, features, advantages, usage methods, tips for selecting the right equipment, and concludes with key takeaways.

Manufacturing Process:

Aerosol filling equipment is manufactured using state-of-the-art technology to meet industry standards and regulations. The meticulous engineering involved ensures that each component functions seamlessly together to achieve optimum efficiency. Special attention is given to design ruggedness while maintaining ease of operation during the manufacturing stage.

Features:

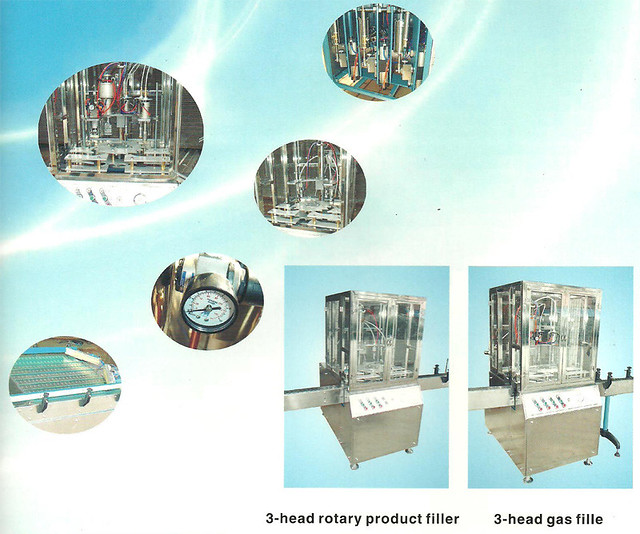

The modern aerosol f Aerosol filling machinery illing machinery comes equipped with numerous innovative features aimed at enhancing productivity. These aerosol filling equipment include automated controls for volume precision, quick-change capabilities for different product lines or containers sizes without compromising on cleanliness standards, integrated filler monitoring systems ensuring error-free operations by detecting any abnormalities promptly.

Advantages:

1. Enhanced Productivity: By utilizing advanced automation technologies like robotics or servo-driven mechanisms combined with user-friendly interfaces allows companies to significantly boost their production output.

2. Cost-Effective Operations: Aerosol filling machines drastically reduce labor costs as they replace RO Water treatment series manual operations with highly efficient automated processes resulting in higher productivity levels.

3. Improved Accuracy: With highly calibrated measuring systems incorporated into these machines ensure consistent spray Sprayer filling system volumes leading to reliable product quality.

4.Safe Handling: Modern sprayer-filling systems prioritize operator safety by implementing comprehensive safety measures such as automatic shutdowns during emergencies or improper handling scenarios.

Usage Methods:

The dispensing equipment designed specifically for producing pesticides encompasses robust structures enabling long-term reliability even under extreme working conditions preventing damage caused by corrosive chemicals used extensively in the formulation. These filling machines come w aerosol filling equipment ith customizable settings to accommodate different container shapes and sizes.

How to Select the Right Aerosol Fillin

g Equipment:

Choosing the appropriate aerosol filling equipment boils down to understanding specific production needs, including volume requirements, product characteristics, and budget constraints. Partnering with a reputable manufacturer is essential for receiving guidance on selecting suitable models based on application demands.

Conclusion:

Aerosol filling equipment plays an indispensable ro Aerosol filling equipment le in meeting consumer demand for various products requiring precise packaging solutions while adhering to strict quality standards. The advanced manufacturing process ensures that these machines provide enhanced efficiency, accuracy, safety, and cost-effectiveness compared to conventional alternatives. When selecting aerosol filling machinery, it is vital to aerosol filling equipment consider specific requirements and partner with trustworthy manufacturers who offer reliable consultation services. Embracing this technology will undoubtedly position businesses at a competitive advantage in today’s dynamic market landscape.