Uniaxial Plastic Geogrid: A Monodirectional Reinforcement Material for Soil Stabilization

Uniaxial Plastic Geogrid: A Monodirectional Reinforcement Material for Soil Stabilization

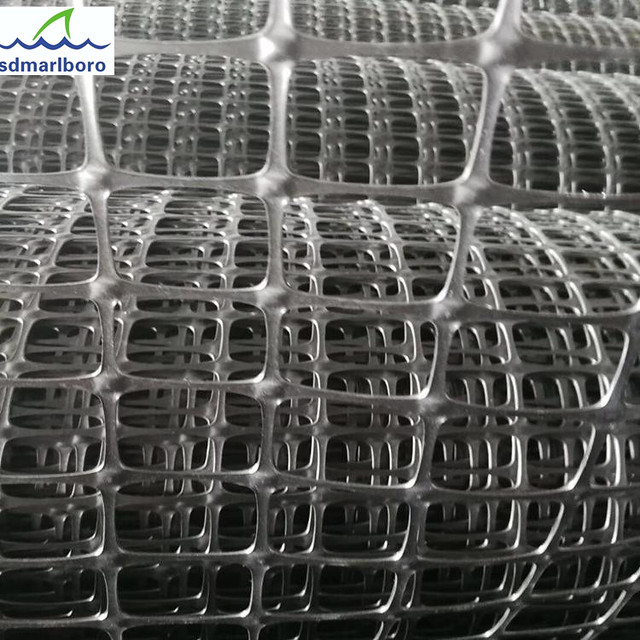

Uniaxial Plastic Geogrid, a Monodirectional Reinforcement Material for Soil Stabilization lso known as Uni-Plastic Geogrid System or One-Way Tensile Strength Polyethylene Mesh, is a versatile and reliable geosynthetic material used in various civil engineering projects. Its unique design and properties make it an ideal choice for soil stabilization and reinforcement applications.

Manufacturin HDPE Dimple Geomembrane g Process:

The Uniaxial Plastic Geogrid is manufactured using high-density polyethylene (HDPE) through a carefully controlled extrusion process. The polymer sheets are stretched in one direction to create a grid-like structure with uniform apertures. These apertures enhance the interlocking ability of the geogrid with surrounding soils.

Key Features:

1. High Tensile Strength: Uniaxial Plastic Geogrid boasts excellent tensile strength, allo HDPE Dimple Geomembrane wing it to resist extensive soil movement and loads.

2. Lightweight Design: The lightweight nature of the geogrid makes it easy to handle during installation.

3. Chemical Resistance: Made from HDPE, this geomembr Uniaxial Plastic Geogrid ane product exhibits superior resistance against chemical degradation and environmental stressors.

4. Durability: Uniaxial Plastic Geogrids are designed to withstand harsh weather conditions, UV radiation, and biological attacks.

Advantages:

1. Improved Soil Stability: By distributing load forces more uniformly within soil structures, Uniaxial Plastic Geogrid enhances stability while preventing deformation under applied loads.

2. Increased Bearing Capacity: With its remarkable tensile strength and reinforce Uniaxial Plastic Geogrid d structure, this geosynthetic material enhances the bearing capacity of weak soils by providing lateral confinement.

3. Reduced Construction Time-Costs: Due to its ease of handling and straightforward installation methodology compared to conventional soil stabilization techniques such as traditional retaining walls or filter bag piling systems, using Uniaxial Plastic Geogrid can significantly reduce project duration and costs.

Usage Guidelines:

1. Identifying Project Requirements: Assess the specific soil stabilization requirements, considering soil types, loads, grade changes, and erosion control needs.

2. Geogrid Selection: Choose the

appropriate type of Uniaxial Plastic Geogrid based on project specifications such as tensile strength, aperture size, and deformation characteristics.

3. Installation Procedure: Prepare the site by clearing vegetation and debris. Ensure proper alignment and overlap of geogrid panels during installation.

4. Backfill Material Selection: Use suitable granular fill materials to maximize interlocking potential with the geogrid structure.

5. Quality Control Measures: Regularly inspect project sites for proper installation techniques Uni-Plastic Geogrid System , adequate compaction levels in backfilled areas, and any signs of damage or instability.

In conclusion, Uniaxial Plastic Geogrid is a highly effective monodirectional reinforcement material that offers numerous advantages for soil stabilization projects. By utilizing its manu One-Way Tensile Strength Polyethylene Mesh facturing process capabilities along with its unique features like high tensile strength and chemical resistance, this geosynthetic product provides exceptional durability while improving overall soil stability. Careful consideration should be given to selecting the right Uniaxial Plastic Geogrid based on specific project requirements to ensure maximum effe Uniaxial Plastic Geogrid ctiveness and long-term success in achieving stable soil structures.

HDPE Dimple Geomembrane/filter bag