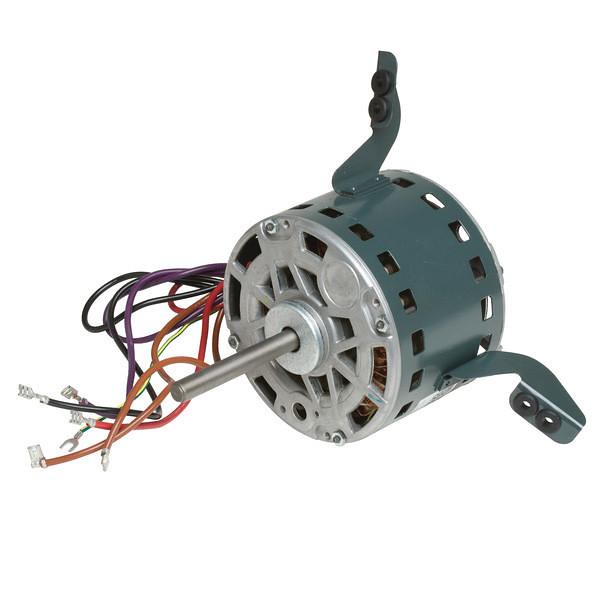

AC Motor: The Key to Efficient and Powerful Electric Machines

Int

roduction:

In today’s fast-paced world, the demand for efficient and powerful electric machines is on the rise. One crucial component in these machines is the AC motor. With its versatility and numerous advantages, it has become an indispensable part of various industries. In this article, we will explore the manufacturing process, characteristics, benefits, usage methods, tips for selecting an A AC motor C motor for your needs.

Manufacturing Process:

The production of AC motors involves several intricate steps. The core components include a rotor and stator assembly made from high-quality materials such as copper and silicon steel laminations. These materials ensure optimal magnetic field generation while minimizing energy losses due to eddy currents. Additionally, state-of-the-art techniqu AC motor es like precision machining are employed to achieve tight tolerances necessary for smooth operation.

Characteristics:

One hallmark feature of AC motors is their ability to convert electrical energy into mechanical power efficiently. Unlike DC motors that require physical brushes or commutation devices leading to frictional losses and maintenance issues over time respectively; AC motors operate brushless using slip rings or magnetically coup Alternating current motor led rotors which significantly reduces wear-and-tear problems.

Advantages:

1) Versatility: AC motors find applications in a wide range of systems including rotary electric machines,

alternating current motor-dri Golf Cart Rear Axle ven pumps,

and even industrial robots.

2) High torque output: Thanks to three-phase power supply used by most industrial setups rendering them capable compared with other alternatives.

3) Better control options: An advanced controller unit can regulate parameters such as speed, torque,

Voltage allowing precise adjustment according to specific application requirements.

4) Lower maintenance costs: Brushless design eliminates the need for frequent brush replacement resulting in reduced dow Brushless AC electric motor ntime and increased overall productivity.

Usage Methods:

There are multiple ways one can utilize AC Motors effectively:

– Industrial Applications: Three-phase induction type commonly empowers heavy machinery instances where controlled starting/stopping operations aren’t crucial.

– Electri Golf Cart Rear Axle c Vehicles: Brushless AC motors are a popular choice due to their efficiency and high power output when compared to traditional internal combustion engines.

– HVAC Systems: AC Motors effectively drive fans, compressors, and blowers in heating, ventilation, and air conditioning systems.

How to Choose the Right AC Motor for Your Needs Rotary electric motor :

Selecting the perfect AC motor requires careful consideration. Here are some factors to keep in mind:

1) Power Requirements: Determine the amount of power needed based on your application requirements.

2) Efficiency: Lo AC motor ok for high-efficiency motors that offer maximum energy savings.

3) Environment considerations: Consider factors such as temperature extremes or hazardous areas requiring special protection ratings.

Conclusion:

The world of electric machines relies heavily on the versatility and effectiveness of AC motors. Their advanced manufacturing processes ensure durability while keeping maintenance costs low. The advantages they provide extend beyond their initial cost investment by maximizing productivity across various industries such as automotive, manufacturing plant setups; even speeding up consumer-level applications like golf

carts thanks to Golf Cart Rear AxleAC motorAC motorAC motorAC motor inclusion. By considering specific needs along with available options in terms of characteristics mentioned earlier selecting an appropriate model won’t be difficult—unleash ultimate performance by harnessing the power provided by AC motor rotary electric machines like brushless AC motors!