Choosing the Right Adhesive Glue

From the translucent goo teachers give preschoolers to the carpenter’s glue used by pros, adhesive glue is everywhere. But choosing the right glue for a specific job can be confusing.

The bond between an adhesive and the surface it adheres to can occur by one of four mechanisms. These include mechanical interlocking, interdiffusion, adsorption and chemical reaction.

Types

An adhesive is an agent that holds two materials together. It may bind materials by mechanical means, in which the glue works its way into small pores of the substrate and sets there, or by one of several chemical mechanisms. The strength of an adhesive bond depends on the type of stress it must withstand. There are three general types of stresses that affect the integrity of an adhesive bond: shear, tensile and compressive.

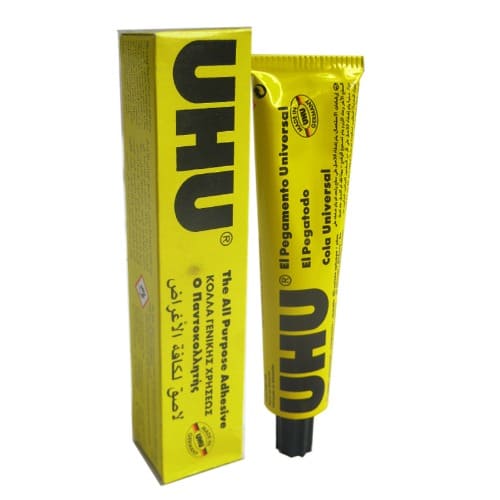

There are many different kinds of adhesive glue. Some require heat to set, while others are instant-curing. adhesive glue There are also solvent-based and water-based varieties, as well as plant and polymer glues. Solvent glues are flammable and evaporate quickly, while water-based ones use water as their solvent. Plant and polymer glues are often derived from natural resins, such as pine rosin or Canada balsam.

There are also special structural adhesives, offered in liquid and paste forms. These are usually used below the glass transition temperature of the polymer (Tg), and include epoxies, cyanoacrylates, urethanes and acrylics. They are designed to bind and support heavy loads, such as those encountered in transportation applications. They are available as a clear or colored product, and can be used to glue woods, plastics, metals and other materials. In some cases, an adhesive can be cured with a hardening catalyst to create a stronger bond.

Adhesives with solvents

These adhesives use solvents (liquid substances that can dissolve other chemicals) to help the glue to set. They are often more tolerant of surface contamination, such as grease or oil, than other types of adhesives. The main problem with solvent-based adhesives is their toxicity and the fact that they emit volatile organic compounds (VOCs). These are damaging to human health and can cause respiratory problems. They also have a very strong smell and can be difficult to work with. It is also important to remember that these types of adhesives are much less stable and will suffer from temperature variations.

There are also a number of different ways that solvent-based adhesives can be applied, including spraying, roller application and brushing. These types of adhesives are often used for jobs that require a fast application speed, or when paper curling must be avoided. They are also very useful for non-porous materials, or when an airtight seal is required.

There are also solvent-free adhesives available which use water to keep the glue wet. These are less harmful to the environment than their solvent-based counterparts and have a much lower odour. However, they are more sensitive to changes in temperature and must be stored correctly to avoid degradation of the product. They can be sprayed, brushed or dripped onto surfaces and have a wide range of uses, including pressure-sensitive applications.

Adhesives without solvents

While adhesives with solvents can be used for a broad range of jobs, there are times when you will require an adhesive that doesn’t contain any harmful solvents. These include when you need a very fast application speed, when you are bonding materials of low surface energy or when you need a high level of strength without having to compromise on flexibility.

These are often known as “non-solvent” or “solvent-free” glues and can be produced using a variety of technologies. They can be manufactured as hot melts, high solids or solventless solutions. They are used when you need an adhesive that dries instantly to a solid phase without any residual solvents or VOCs (volatile organic compounds).

Non-solvent adhesives can also be produced from natural substances such as animal or vegetable oils, resins and waxes. They can be used for a wide range of jobs and are particularly suitable for those materials that do not accept any other type of adhesive such as metals, glass or plastic.

Solvent-free glues do not evaporate as quickly as those with solvents and therefore tend to have a longer cure time. They are also more sensitive to temperature variations and can struggle in colder conditions or outdoor adhesive glue exposure. Some formulations have a primer or treatment which is applied to the substrate before the adhesive is used. This will improve the effectiveness of the bond and help it to resist moisture.

Applications

Adhesive glue is used for many applications, from repairing small household items to joining large industrial materials. The choice of adhesive depends on the material to be bonded, surface conditions, temperature and other environmental factors. Some adhesives are formulated to resist certain environmental factors, such as moisture, UV radiation and chemicals.

Almost all synthetic and some natural adhesives contain polymers, giant molecules made by linking thousands of simpler monomers. Polymers impart strength, flexibility and the ability to spread and interact on an adherend surface. These properties are essential for acceptable adhesion levels. Polymerization can take place during a cure step, in which case the adhesive forms as it sets, as is the case with epoxy resins and cyanoacrylates, or it can happen before application as with thermoplastic elastomers such as styrene-isoprene-styrene block copolymers.

Some adhesives are designed to be removed after a period of time, without leaving residue on the adherend. These are known as removable adhesives, and include pressure-sensitive adhesives, such as Post-it Notes. Others are intended to remain permanently bonded, such as surface protection films and masking tapes.

Some adhesives are also formulated to be biodegradable, allowing them to be absorbed by the environment without harming it. Examples are gecko-inspired and marine-inspired bioadhesives, which bind proteins to surfaces. These are a growing alternative to synthetic glues such as cyanoacrylates, which have a negative impact on the environment and human health.